Keyhole pores reduction in laser powder bed fusion additive

By A Mystery Man Writer

Deep learning-based data registration of melt-pool-monitoring images for laser powder bed fusion additive manufacturing - ScienceDirect

Achieving superelastic shape recoverability in smart flexible CuAlMn metamaterials via 3D printing - ScienceDirect

A Route for Avoiding Defects During Additive Manufacturing - News - Carnegie Mellon University

Towards material and process agnostic features for the classification of pore types in metal additive manufacturing - ScienceDirect

M. DONMEZ, National Institute of Standards and Technology, NIST, Intelligent Systems Division

Felix KIM, Mechanical Engineer, PhD, National Institute of Standards and Technology, NIST, Intelligent Systems Division

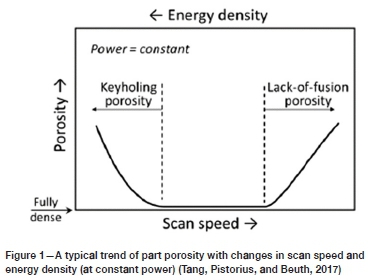

A route for avoiding defects during additive manufacturing

Defect-based analysis of the laser powder bed fusion process using X-ray data

/en/wp-content/uploads/sites/2/20

PDF) LASER PATH PLANNING AND POWER CONTROL STRATEGIES FOR POWDER BED FUSION SYSTEMS

PDF) Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion

Characterization of additively manufactured AlSilOMg cubes with different porosities