The effects of spray drying, HPMCAS grade, and compression speed

By A Mystery Man Writer

Spray dried dispersions (SDDs) have the potential to dramatically improve the oral bioavailability of drugs with poor water solubility. However, SDDs tend

Spray dried dispersions (SDDs) have the potential to dramatically improve the oral bioavailability of drugs with poor water solubility. However, SDDs tend to have material attributes, such as small particle size, low bulk density, and poor flowabilit

View of FORMULATION AND CHARACTERIZATION OF HPMC AND HPMCAS BASED

PDF] Utility of Films to Anticipate Effect of Drug Load and Polymer on Dissolution Performance from Tablets of Amorphous Itraconazole Spray-Dried Dispersions

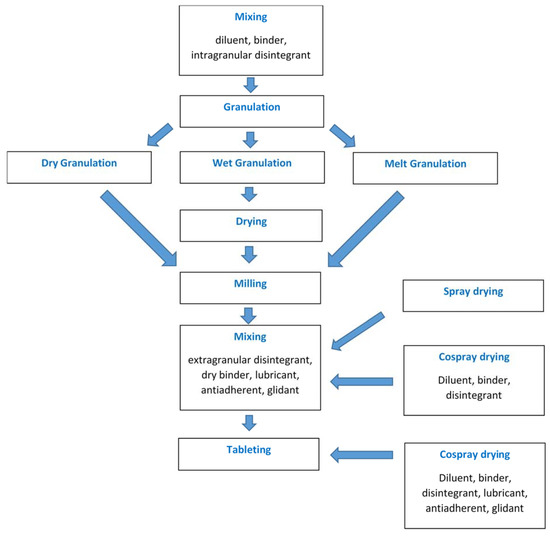

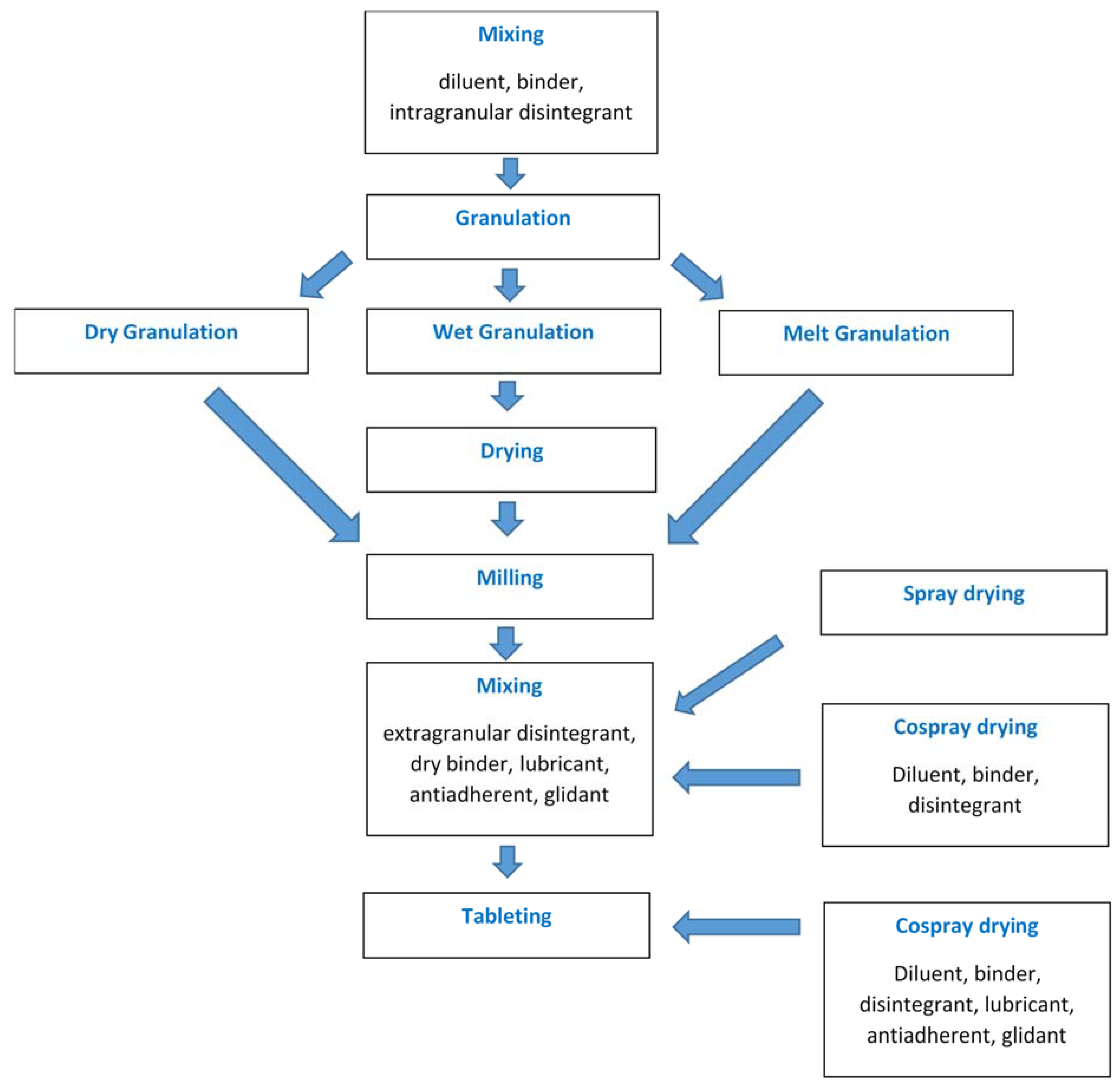

Processes, Free Full-Text

Utility of Films to Anticipate Effect of Drug Load and Polymer on

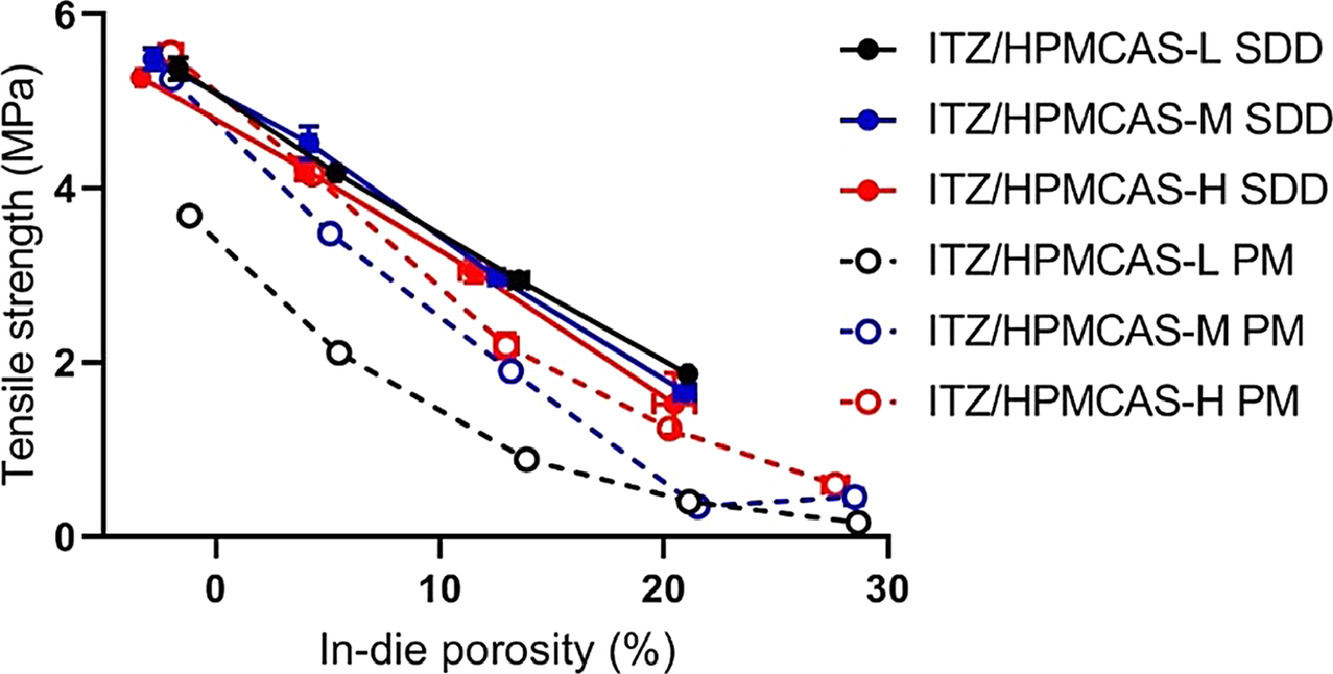

Characterization of Grades of HPMCAS Spray Dried Dispersions of

Downstream processing of spray-dried ASD with hypromellose acetate

PDF] Utility of Films to Anticipate Effect of Drug Load and

Moshe Honick - Biopharmaceutics Reviewer - FDA

Spray Drying for Direct Compression of Pharmaceuticals - Pharma

Utility of Films to Anticipate Effect of Drug Load and Polymer on

PDF] The impact of hot melt extrusion and spray drying on

Sharmila DAS, Clinical Pharmacologist, Doctor of Philosophy, Bristol-Myers Squibb, New York City, B-MS, Department of Pharmacology

Concordance of vacuum compression molding with spray drying in screening of amorphous solid dispersions of itraconazole - ScienceDirect

- LONGLUAN Royalaura Medical Grade Compression Stockings, Medical Compression Socks for Women, Medias De Compresion para Varices, Medical Grade

- Medical Grade Compression Socks 20-30 mmHg - My Ice Wrap

- Ziperior Inside Leg Zipper 20-30 mmHg Compression Grade Calf Closed Toe Socks (Black, X-Small) : Health & Household

- Skineez Medical Grade Moderate Compression Foot And Ankle Sleeve – Skineez®

- The Benefits of Medical-Grade Compression in Treating Chronic

- No Name Barbecue Potato Chips 200g/7.1 oz., {Imported from Canada}

- Egg in a Hole - Simply Happy Foodie

- Buy Selfcare New Collection Women T-Shirt Lightly Padded Bra

)

- Lace Flare Dress Shop Old Night Out Dresses at Papaya Clothing

- nsendm Female Underwear Adult Dark Lingerie Set Silk Sexy Sleepwear Stain Lingerie Lace Bodysuit Pajamas Jumpsuit Bow V-Neck Sexy Lingerie