Fiber movement during compression molding simulations with the ribbed

By A Mystery Man Writer

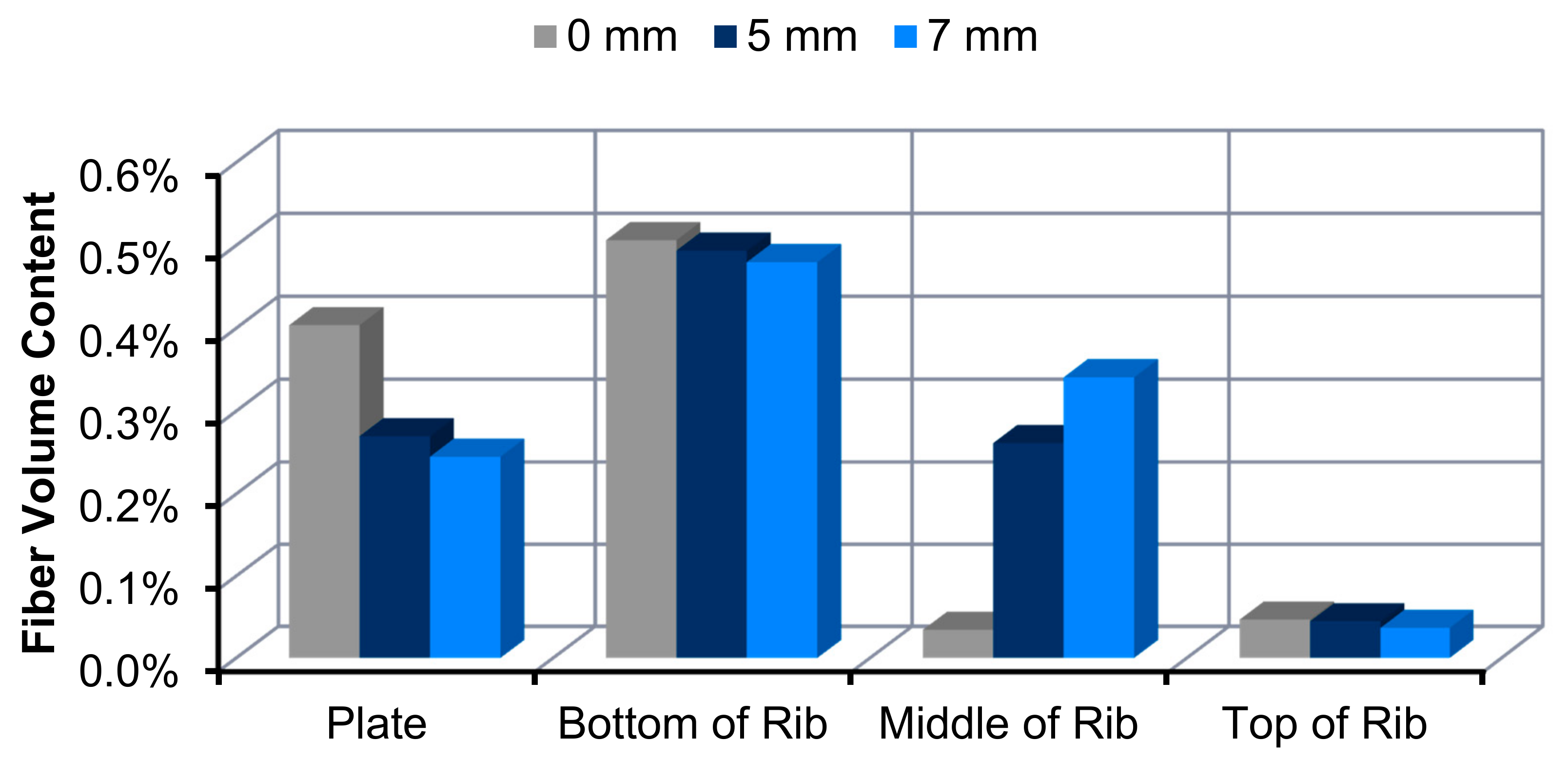

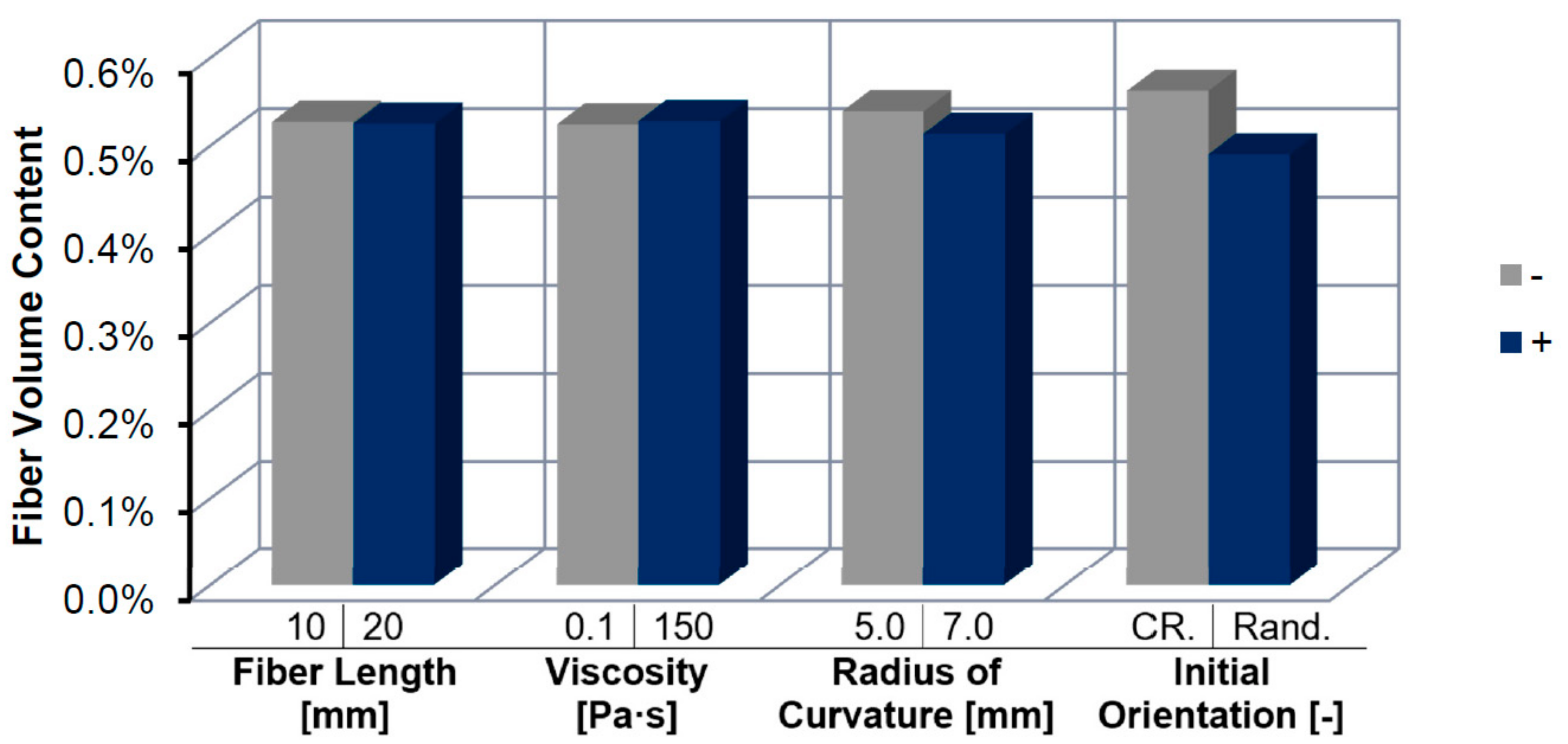

Download scientific diagram | Fiber movement during compression molding simulations with the ribbed plate at consecutive time steps 1-4. from publication: Simulative Prediction of Fiber-Matrix Separation in Rib Filling During Compression Molding Using a Direct Fiber Simulation | Compression molding of long fiber reinforced composites offers specific advantages in automotive applications due to the high strength to weight ratio, the comparably low tooling costs and short cycle times. However, the manufacturing process of long fiber composite parts | Fiber, Compression Molding and Reinforcement (Psychology) | ResearchGate, the professional network for scientists.

Christoph KUHN, Research Project Manager, Dr.-Ing., Volkswagen AG, Wolfsburg, Group Research

J. Compos. Sci., Free Full-Text

Ian WALTER, Research Assistant, University of Wisconsin–Madison, Wisconsin, UW, Department of Mechanical Engineering

Fiber movement during compression molding simulations with the ribbed

A Commercial tire tread pattern of PCR 205/55R16.

Micrographic pictures showing void content in the peripheral (poor

J. Compos. Sci., Free Full-Text

Olaf TAEGER, Head of Polymers, Volkswagen AG, Wolfsburg, VW Group Reserach

Micrographic pictures showing void content in the peripheral (poor

Mechanism of air-pumping noise.

Ian WALTER, Research Assistant, University of Wisconsin–Madison, Wisconsin, UW, Department of Mechanical Engineering

Micrographic pictures showing void content in the peripheral (poor

PDF) Simulative Prediction of Fiber-Matrix Separation in Rib Filling During Compression Molding Using a Direct Fiber Simulation

- Men's Bodybuilding - Open Heavyweight-1st - Goldwin Teskey…

- Top Construction Equipment Manufacturers in World and Market

- If you want to lose love handles then make sure to use our best

- Priest Costume Set - Standard Size (Includes Robe, Collar and Stole) - Perfect for Role Play, Church Events, Theater Performances, Halloween Parties and Other Events : Clothing, Shoes & Jewelry

- Fabletics Kathie seamless mock neck tank top sleeveless pink small