Sensors, Free Full-Text

By A Mystery Man Writer

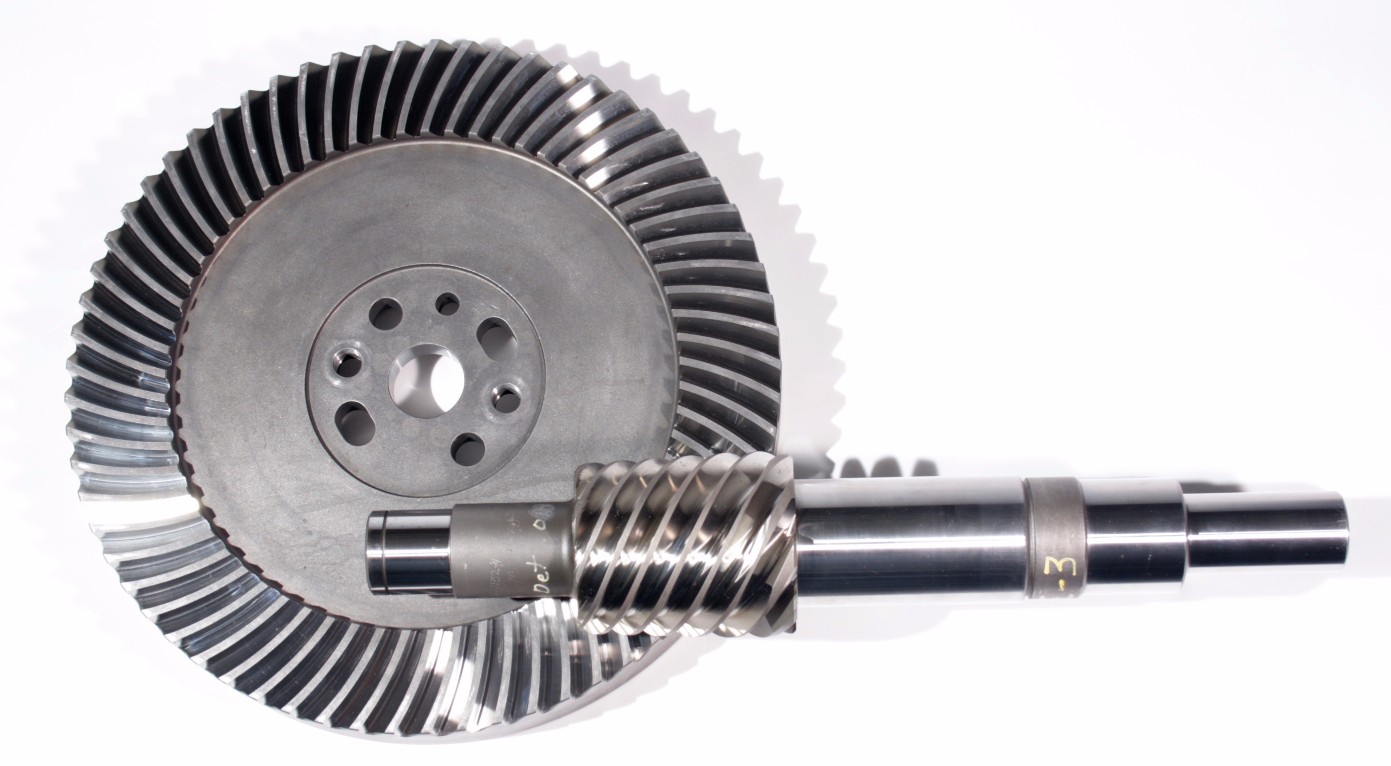

Surface defect detection and dimension measurement of automotive bevel gears by manual inspection are costly, inefficient, low speed and low accuracy. In order to solve these problems, a synthetic bevel gear quality inspection system based on multi-camera vision technology is developed. The system can detect surface defects and measure gear dimensions simultaneously. Three efficient algorithms named Neighborhood Average Difference (NAD), Circle Approximation Method (CAM) and Fast Rotation-Position (FRP) are proposed. The system can detect knock damage, cracks, scratches, dents, gibbosity or repeated cutting of the spline, etc. The smallest detectable defect is 0.4 mm × 0.4 mm and the precision of dimension measurement is about 40–50 μm. One inspection process takes no more than 1.3 s. Both precision and speed meet the requirements of real-time online inspection in bevel gear production.

Sensors, Free Full-Text, Armature

Sensors, Free Full-Text, bldc motor

ae01.alicdn.com/kf/S3136ba5762594225a6114c35a71699

Air Intake Pressure Sensor,MAP Sensor 079800-3000 : : Automotive

New High Resolution Sensors

Sensor Images - Free Download on Freepik

Sensors, Free Full-Text, thomas mitchell overton execution

Sensors, Free Full-Text, mini box ribeiro

Sensors, Free Full-Text, ray manchester x reader

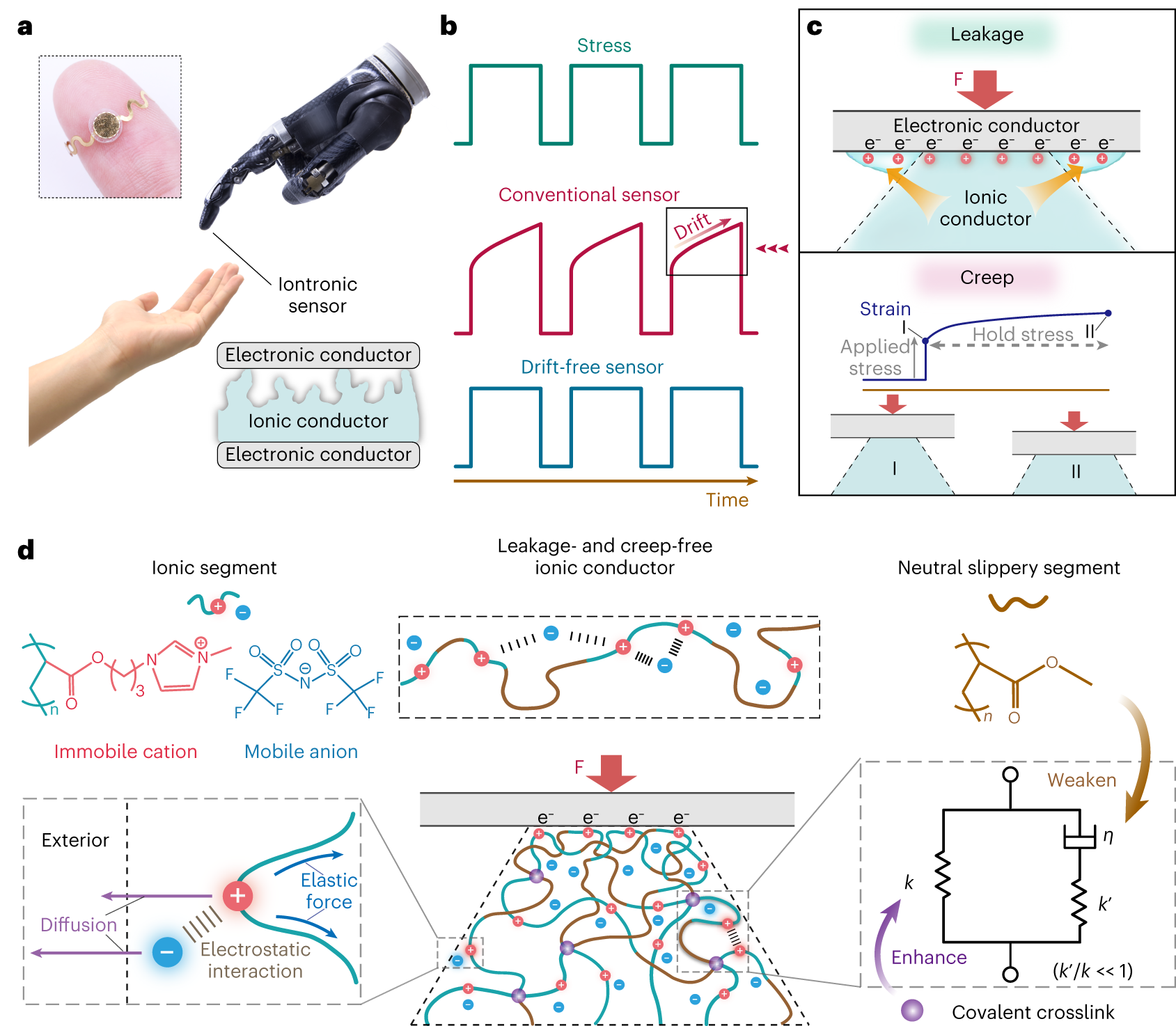

Creep-free polyelectrolyte elastomer for drift-free iontronic sensing

Sensors, Free Full-Text

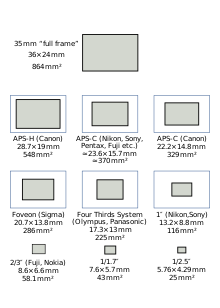

Digital camera - Wikipedia

Sensors, Free Full-Text

Mini 3 Color Sensor – Nix Sensor Ltd

- NKOOGH Agogie Pants Women'S Dress Pants for Work Business Casual Trousers Pant Bottoms Trousers Summer Long Drawstring With Pockets Women'S Pants

- Brehme gaffe, diretta social e l'ex Inter e inquadra la moglie

- rat fink ed big daddy roth sidewalk surfer, brocklyncheese

- Custom Branded Grip Socks

- Leggings High Waist Fashion Women Joggers Sport Fitness Yoga Pants Butt Lift Long Trousers Ladies Comfy Casual Gray Sweatpants - AliExpress